Temperature Sensitivity of 9 Powders for .223 High Power Service Rifle

Identification of Substitution/Replacement Powders for Varget and IMR 8208 XBR in Target Shooting

The goal of this study was to identify substitute or replacement powders for Varget and IMR 8208 XBR for use in .223 service rifles in high power rifle matches as well as in 200 yard practice. Varget and IMR 8208 XBR are both powders that provide consistent accuracy and high velocity for .223 ammunition across a wide range of temperatures. Both powders are produced by Thales Australia Ltd and are imported into the USA. There have been recurring shortages of these powders because of high demand and limited production. Both powders have been recently restricted from import into the European Union because of toxic chemicals that they contain that are restricted by the EU REACH initiative (see more HERE.) Their continued ready availability is unknown.

The first objective was to identify powders that provide comparable velocity for .223 match and practice bullets and comparable or better insensitivity to temperature-induced velocity variation. I was particularly interested in four newer powders that claim temperature insensitivity and/or reduced copper fouling that are EU REACH acceptable (i.e, IMR 4166, AR Comp, CFE 223 and Lovex S062). I included older powders with known sensitivity to high-temperature increase in velocity (e.g., H335) as controls in the tests. I also conducted initial accuracy tests for the best performing powders. Tests were run initially at cartridge temperatures from 34°F to 102°F (1 to 39°C) which cover temperatures that I encounter at matches in North and Central Florida and are technically feasible to run with my available resources. When subsequent temperature measurement showed that cartridges were subjected to chamber temperatures of up to 142°F during the course of a slow-fire or rapid-fire match, I extended the temperature sensitivity tests out to 129 to 131°F for several powders of greatest interest.

My ideal replacement powder for Varget for use in a .223 service rifle (.223 Wylde chamber) in high power midrange matches would:

- Produce high muzzle velocity: 2700 to 2750 FPS with 77 grain Sierra MatchKing bullets for 200-300 yard distance; 2650 to 2700 FPS with 80-80.5 grain bullets for 600 yard distance;

- Produce comparable or better temperature-insensitivity to Varget over a wide temperature range - 34°F to 131°F (1°C to 55°C);

- Not require compression packing of powder and over-pressure to achieve target velocities;

- Provide consistent propulsion for 77 to 80.5 grain bullets (i.e., low velocity standard deviation)

|

Two powder loads that I have used for high power rifle matches and practice that were used as standards to compare with other powder performance were:

Standard Load 1. 77 grain Sierra MatchKing bullet, 23.8 grains Varget, Lapua 223 Match brass (reloaded), CCI 41 primer, 2.26 inch COL. Muzzle velocity: 2706 FPS (SD 23) at 80°F with 20 inch 1:7 twist barrel .223 Wylde chambered AR-15. Accuracy at 200 yards is 0.8 MOA with a match-grade service rifle. Service rifle accuracy at 300 yards is 1.0 MOA. This is a load that I use for 200 and 300 yard Across-the-Course (ATC or XTC) high power matches.

Standard Load 2. 55 grain Hornady FMJ-BT bullet, 25.5 grains IMR 8208 XBR, once fired Lake City 5.56 NATO brass (reloaded), CCI 41 primer, 2.20 COL. Muzzle velocity: 3198 FPS (SD 24) at 78°F with 20 inch 1:7 twist barrel .223 Wylde chambered AR-15. Accuracy at 200 yards is 1.2 MOA with a service rifle. This is a practice load that I use for off-hand standing and rapid-fire sitting at 200 yards.

Design and Methods:

I used QuikLOAD V.3.9 software (2020 data version) to determine powder loads that would give comparable estimated velocities per bullet without exceeding estimated cartridge pressures of 55,000 psi (maximum SAAMI standard for .223 Remington.)

• Method information (rifle, chronograph, brass preparation, powder measurement and temperature control) is HERE.

• Information on powder manufacturers, USA distributors and powder lot number is HERE.

• Summary data with QuickLOAD data on powder charge, predicted velocity and pressure, etc. are HERE.

|

Results/Data:

QuickLOAD provided a reasonable first estimate of velocities for most powder-bullet combinations to match standard load 1 with 77 grain MatchKing bullets and to match standard load 2 with 55 grain bullets.

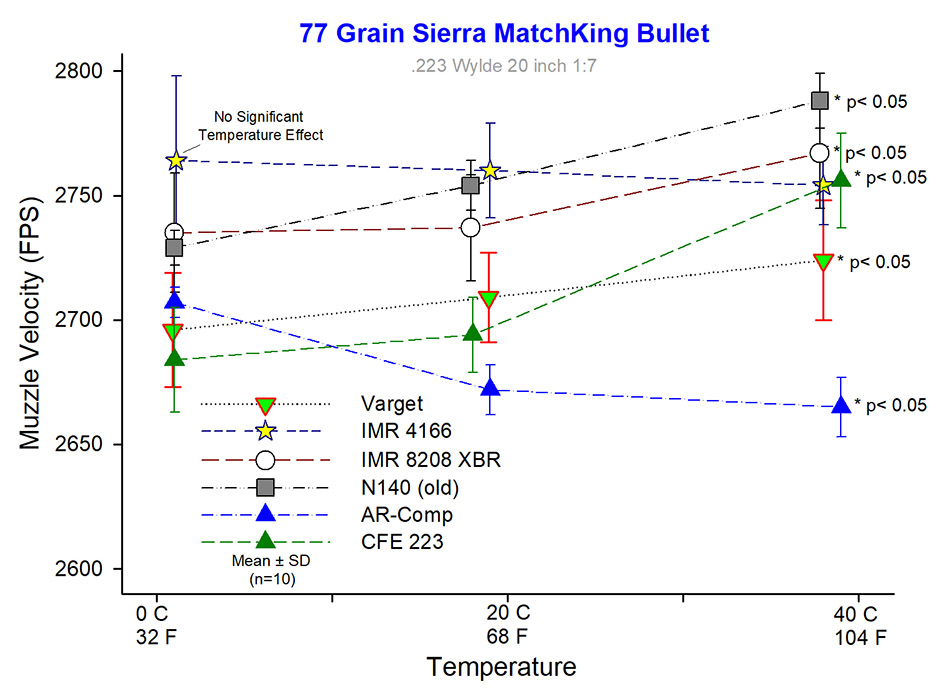

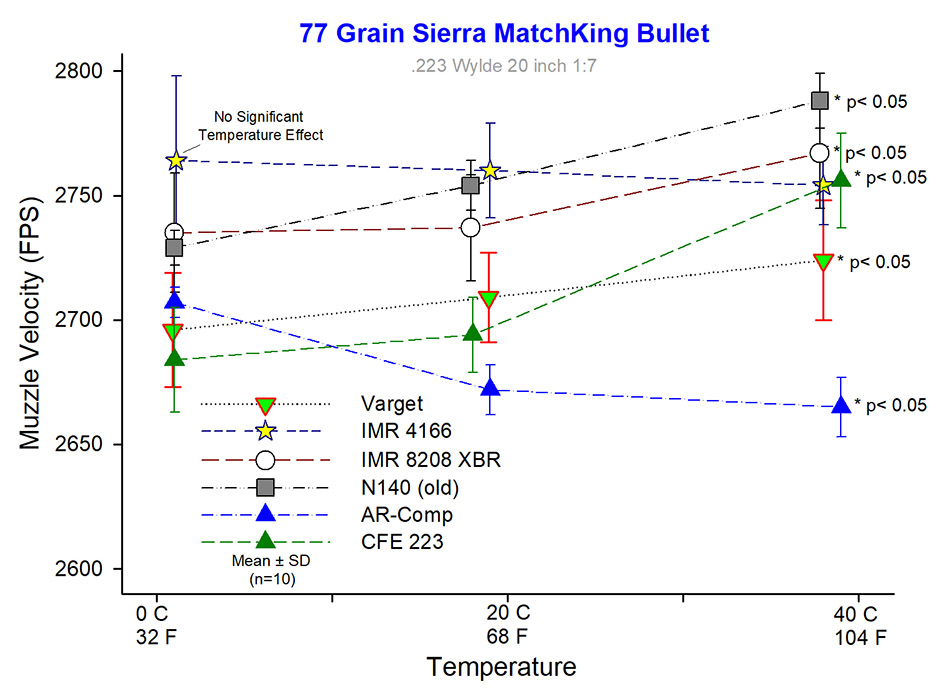

77 grain Sierra MatchKing

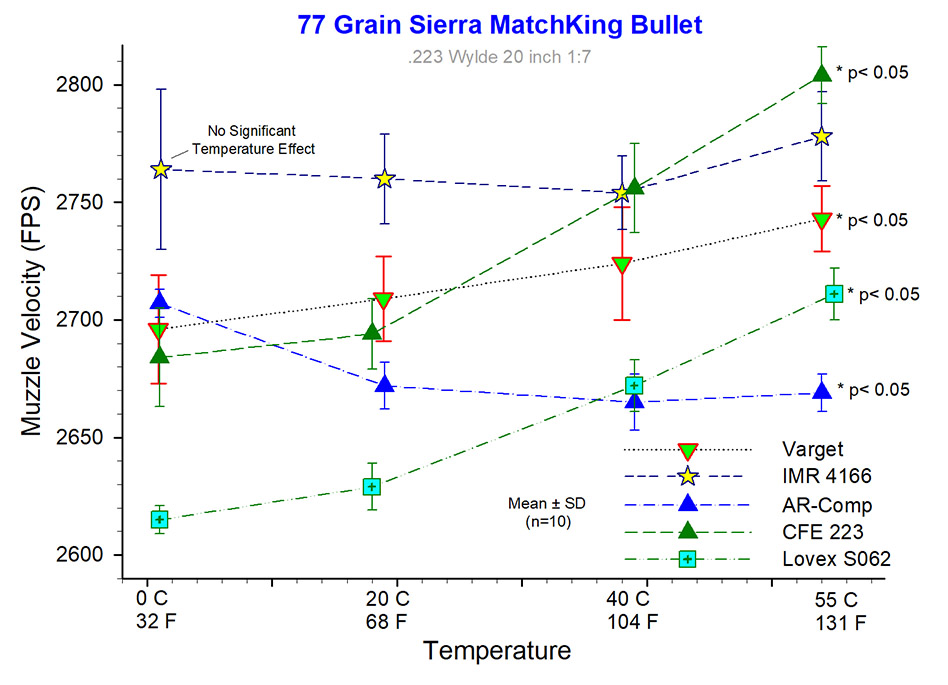

Figure 1 - Initial screen of temperature sensitivity of powders at 3 temperatures

Numeric Data with Statistical Analysis is shown in Table 1 and Table 2. The difference in impact point across the velocity extremes at 300 yards is in Table 3. |

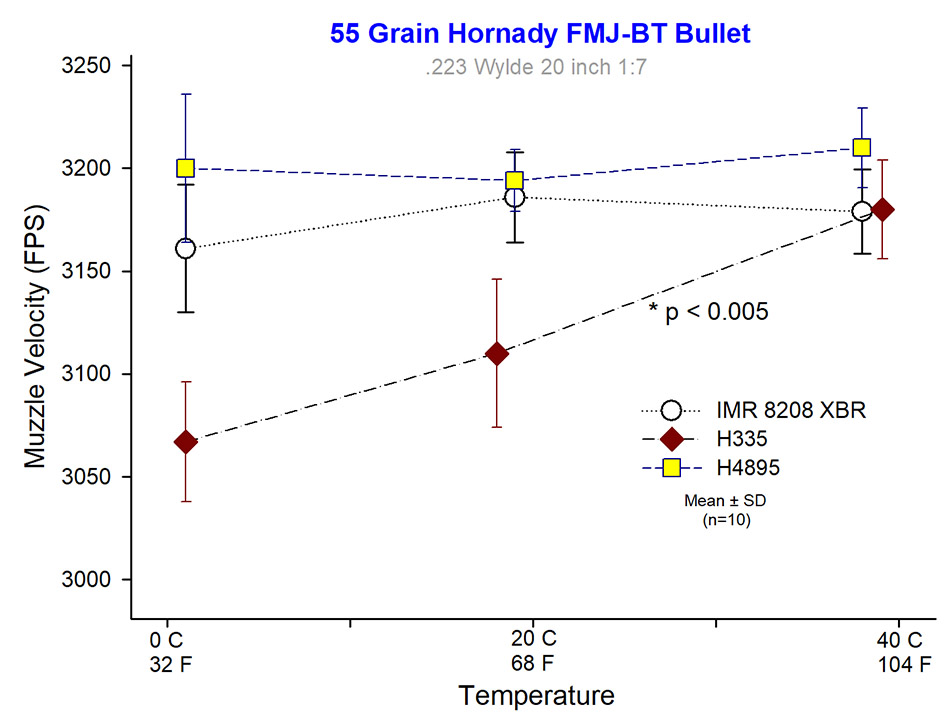

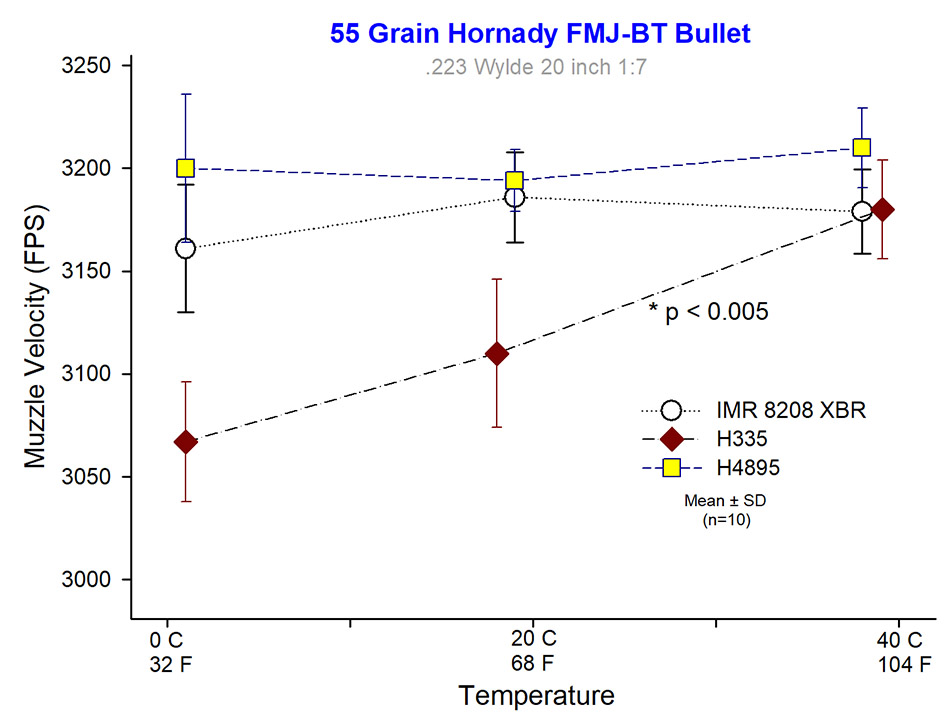

55 Grain Hornady FMJ-BT Bullet for Practice

Only two powders were compared to IMR 8208 XBR for 55 grain practice bullets (Tables 4 and 5, Figure 2). H4895 was evaluated because I use this powder for 30 caliber ammunition, and it is often easier to find for sale than is IMR 8208. H335 was evaluated as a positive control for a temperature sensitive powder based on its reputation from online forums. Both IMR 8208 and H4895 were relatively temperature insensitive with the tested loads although statistical power was low at n=10. H335 was the most sensitive to temperature-induced bullet velocity changes of the powders that were evaluated.

Figure 2 |

Numeric data and statistical analysis of the 55 grain bullet data is in Tables 4 and 5.

Further consideration of temperature effects on powders when shooting

77-80 grain bullets

Temperature sensitivity tests run in the first part of the study identified powders that were relatively temperature-sensitive compared to Varget (e.g., CFE 223 and N140). It also identified powders that may be more resistant to temperature-induced variations in velocity (i.e., IMR 4166 and AR-Comp.) Review of initial results by members of Accurate Shooter Shooter's Forum identified several areas where the study could be improved: 1) Study of two other powders; and 2) Consideration of the effects of chamber temperature on powder temperature during ignition/combustion.

New Formulations of Powder Not Considered:

In looking for a replacement/substitution powder for Varget, I neglected to include Lovex S062 (Shooters World Precision Rifle Powder). I subsequently included it in the study. N140 purchased in 2020 was found to be moderately temperature sensitive. A newer version of the powder was obtained in 2021 which was reported (and advertised) to be "temperature-stable." This new powder had different temperature-sensitivity to the old. However, it was still moderately temperature sensitive above 68°F. (See study data here.)

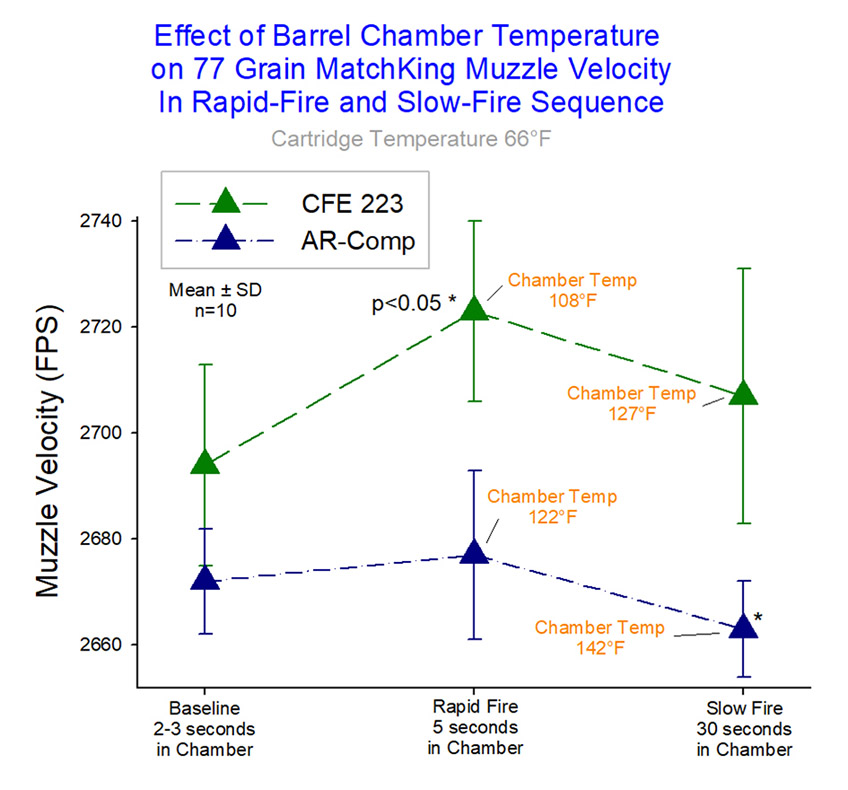

Effect of Chamber Temperature in Cartridges (See Associated Study with Tables 6 and 7)

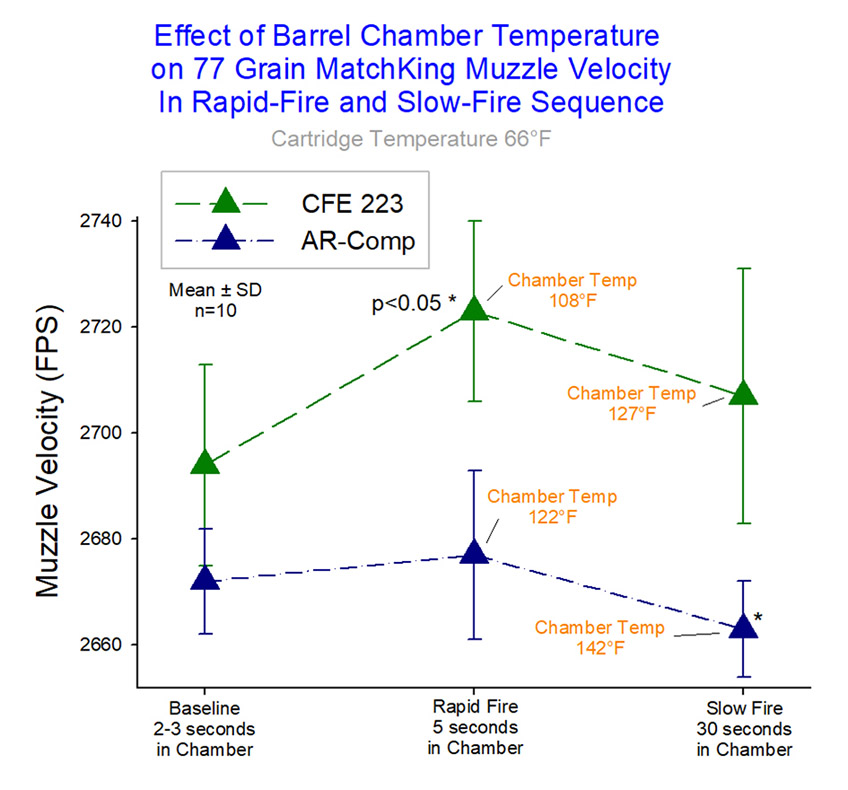

I looked at the effects of loading a cartridge at mild ambient temperature (66°F) into a hot chamber simulating the middle of a 20 slow-fire string or the second 10-shot rapid-fire string. Once the rifle chamber got hot, cartridges loaded into the chamber for 5 to 30 seconds did heat the powder and significantly change muzzle velocity (Figure 3).

Figure 3

|

The effects of this chamber heating of the cartridge are shown in Tables 6 and 7. The spread of impact points at 600 yards for a temperature-sensitive powder such as CFE 223 could be as much as 7.2 inches (moving your perfectly aimed shot outside the 7 inch X-ring.) In contrast, the effect of chamber heating of the cartridge for a more temperature-resistant powder such as AR-Comp would result in less than half as much impact spread at 600 yards (See data and explanation associated with Tables 6 and 7).

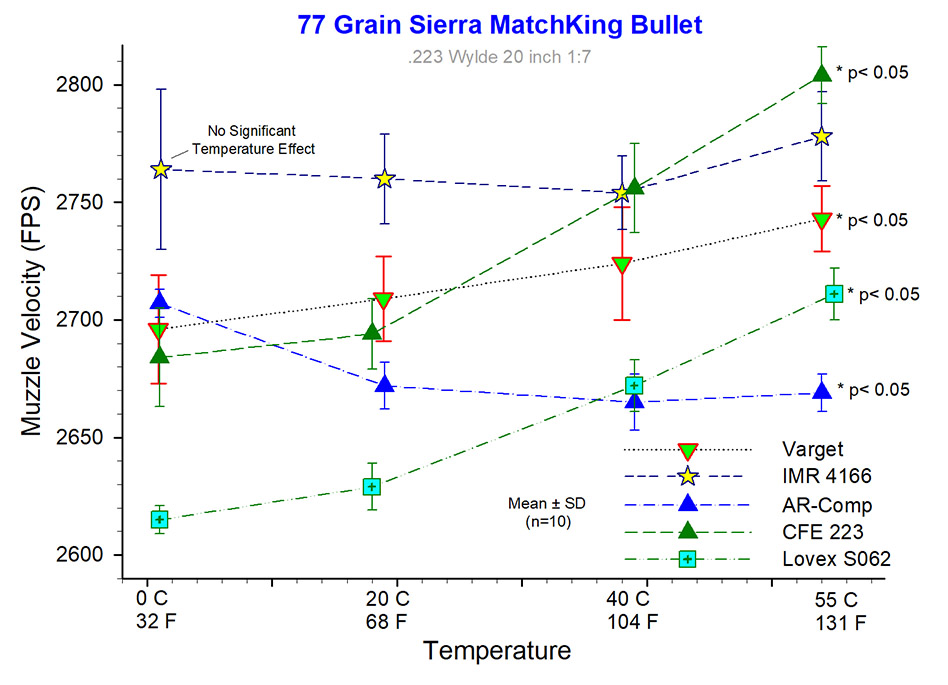

The fact that cartridges in the middle of a slow-fire string could have prolonged exposure in the chamber to temperatures of 108 to 142°F before being fired warranted study of powder sensitivity at higher temperatures. Temperature sensitivity is plotted below from 34°F to 129°F (Figure 4).

Figure 4: *p<0.05, Temperature sensitive by one-way ANOVA, Holm-Sidak comparison test. Numeric data is in Table 1. |

Table 8. Temperature sensitivity of newer powders compared to Varget

Summary of Findings/Discussion

IMR 4166 and Varget were the least sensitive powders to temperature-induced bullet velocity changes for 77 grain MatchKing bullets between 34 and 129°F. AR-Comp had the least temperature sensitivity between 68 and 131°F and the smallest standard deviations in velocity. Each powder evaluated had performance features worth noting.

Varget: This remains a favorite propellant for 77 to 80 grain bullets for high power .223 service rifle shooters. It has outstanding accuracy and relatively consistent velocity performance across a wide temperature range. Availability in the USA remains a problem for many shooters.

IMR 4166: This newer propellant produced by General Dynamics in Canada had the best temperature insensitivity and may be the best substitute for Varget across a wide temperature range with 77 to 80 grain bullets. In another study, IMR 4166 was identified as the best replacement for Varget between 61°F and 103°F for .308 F-TR rifles. (see note 1).

AR-Comp: This newer propellant manufactured for Alliant by Eurenco Bofors AB in Sweden (RP-34TZ) has interesting temperature response properties and velocity consistency. The Eurenco Bofors powder catalog has temperature-velocity data showing that RP-34TZ has its fastest velocity at -29°C (-20°F) and slowest velocity at 52°C (126°F) with overall velocity variation being comparatively small to that of other powders across the temperature range. The powder had no significant changes in velocity between 66°F and 129°F in this study. The low standard deviation in velocity compared to most other powders offers the possibility that it could provide greater shot-to-shot consistency (accuracy) than Varget for prone shooting with service rifles between 300 and 600 yards.

CFE 223: This powder had moderately high temperature sensitivity between 64°F and 129°F with 77 grain bullets. However, it showed more stable velocity performance between 34°F and 64°F. It was not evaluated with 55 grain bullets.

Lovex S062: This powder marketed in the USA as Shooters World Precision Rifle showed moderate temperature sensitivity similar to that of N140 and CFE 223. It had low standard deviations in velocity similar to old N140 and AR-Comp.

IMR 8208 XBR: This was the 3rd most resistant powder to temperature-induced velocity variations with 77 grain bullets between 34 and 102°F. No temperature-induced velocity variation was measured with 55 grain bullets. It was not tested at 129°F. Despite being a faster burning powder, I have found it to outperform the accuracy of Varget in one of my service rifles at 300 yards with 77 grain tipped MatchKings. As with Varget, availability continues to be a problem in the USA.

N140: The Vihtavuori powder that I purchased in 2020 showed moderate temperature sensitivity but had low standard deviations in velocity at each temperature. New N140 had similar temperature sensitivity above 68F. See Comparison of Old vs New N140..

H4895: This powder showed no temperature sensitivity between 34°F and 102°F with 55 grain bullets. It was not evaluated with 77 grain bullets.

H335: This was a positive control in the study for a temperature-sensitive powder. It generally is much more readily available than either Varget or IMR 8208 XBR in the USA. The maximum estimated shift in point of impact at 200 yards between 34°F and 102°F on a SR target is only 0.6 inches. It meters very accurately, so charging cases during reloading is very fast. It is a perfectly acceptable choice for 55 grain FMJ-BT practice rounds if awareness of temperature sensitivity is considered in choosing a loading charge.

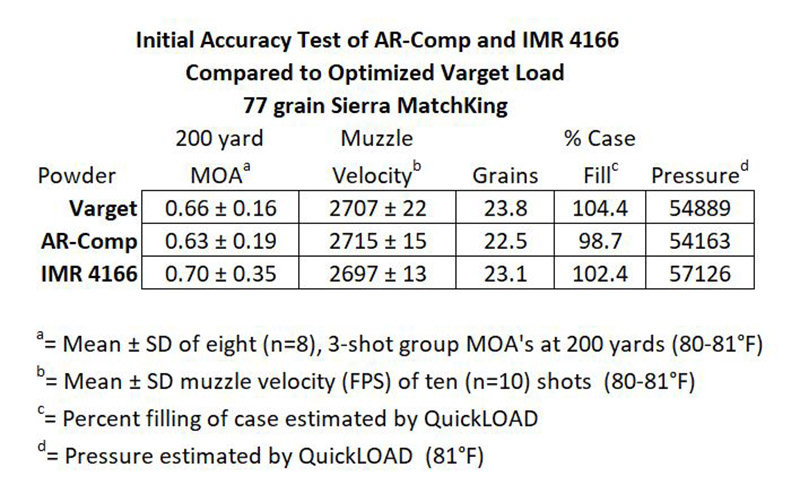

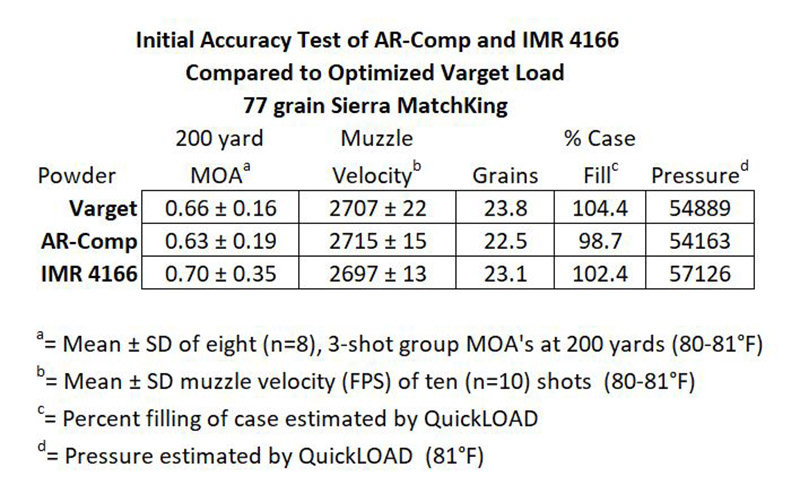

First Shot at Accuracy Testing

I used QuickLOAD to estimate powder charges for AR-Comp and IMR 4166 that would give velocity close to that of the rifle-optimized load I use with 77 grain Sierra MatchKing bullets (Standard Load 1 listed above). Rifle and bullets were tested at ambient temperatures of 80-80°F as described. At 200 yards, accuracy MOA's of the non-optimized charges for AR-Comp and IMR 4166 yielded MOA's very close to that of the rifle-optimized Varget cartridge (Table 9.)

Table 9

|

Conclusions

The major goal of this study was to identify substitute/replacement powders for Varget in shooting 77 to 80 grain bullets in .223 high power service rifle matches. Temperature sensitivity tests identified two newer powders (IMR 4166 and AR-Comp) that had comparable temperature insensitivity to that of Varget between 64 and 131°F and that also provided comparable velocity and accuracy to Varget with 77 grain Sierra MatchKings at 200 yards.

Home

First posted for review 8 August, 2021, last revision 21 August, 2021

© 2021, William L. Castleman

Figure 4: *p<0.05, Temperature sensitive by one-way ANOVA, Holm-Sidak comparison test. Numeric data is in

Figure 4: *p<0.05, Temperature sensitive by one-way ANOVA, Holm-Sidak comparison test. Numeric data is in